The smart all-rounder – Driverless Underride Transport Shuttle FS400 from Neumaier Industry

In times of digitalisation and Industry 4.0, a reliable and innovative flow of goods within production is the key to success. Automated guided vehicles (AGVs) are becoming increasingly important in intralogistics and can be optimally integrated into the overall automation concept of a factory.

The fact that Neumaier Industry GmbH & Co. KG was able to realise such an AGV solution, from conception to delivery, within a very short time is more than remarkable. The reason for this was a customer's request: to transport goods between production and warehouse in an automated and, above all, safe manner, that was the task set.

"Our customer approached us. He was looking for a partner who could offer him a holistic automation solution as a complete package," says Daniel Munz, Marketing Manager at Neumaier Industry GmbH. The driverless underride transport shuttles were on the project list for development anyway and were then brought forward without further ado. A total of five Factory Shuttle FS400s (the official name of the compact Neumaier AGVs) were developed within a very short time and successfully put into operation at the end customer. Added to this were several source sinks and special trolleys, a management system with touch display and graphical user interface, as well as a sophisticated traffic light control system for regulating the traffic of the automated and manual vehicles.

Uncomplicated, flexible, short delivery times – Drive technology from HIWIN was set

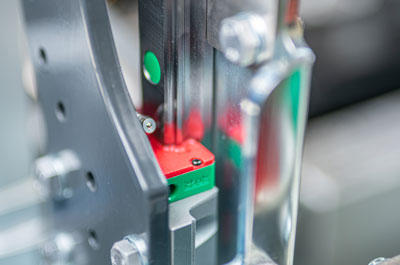

HIWIN drive technology is also installed in the smart and automated shuttles: Profile rail guides from the EG series are responsible for guiding the lifting movement of the load carrier safely and precisely. The integrated electrically driven lifting mechanism achieves a standard lifting height of up to 100 mm with integrated overload protection.

Not only can it move to the zero and end positions, but intermediate stages are also possible and can be individually programmed.

"At first we had designed the shuttle with ball-bearing guides. Towards the end of the design phase, however, we ran out of space, so we asked for linear guides after all," smiled Neumaier's designer. "The HIWIN field service responsible for us immediately suggested the right product for us. Years of customer service just pay off."

A conscious decision was made in favour of the flat EG version. The series is especially suitable for applications with limited installation space. With the four ball tracks arranged at an angle of 45°, particularly high loads can be accommodated equally in all directions, which is ideal for use in a driverless underride transport shuttle.

"The profile rail guides of the EG series were set. The previous configuration with the CAD configurator on the HIWIN website also supported us once again in our decision. We have been working with HIWIN for a long time. They already supply us with their products for our tugger trains and our narrow-aisle forklifts - we are very satisfied. The uncomplicated, flexible cooperation and above all the short delivery times have always convinced us. The quality and the price-performance ratio simply fit," praised Neumaier's design engineer.

The technology of the FS400

The driverless underride transport shuttle is driven by a 2-way drive/steering system (optionally also omnidirectional). A lithium iron phosphate battery (Li-FePo4) provides the necessary power. The shuttle charges itself, as the FS400 automatically connects to the stationary charging station when the battery reaches a certain level.

The navigation and orientation of the AGV is done by geonavigation / SLAM with a previously created virtual mapped map.

The shuttle's scanner scans its surroundings and transfers the mapping to the software supplied. There, the route of the shuttle can then be determined conveniently on the PC. Changing or adapting routes or sources/sinks can also be done directly by the user - this makes it extremely flexible and uncomplicated for the customer.

Compared to a classic, driver-guided floor vehicle, the FS400 offers many advantages. Internal material flows can be automated in the best possible way, costs can be saved and operational safety can be increased. "With the integrated PL-d laser scanner, the transport shuttle can detect obstacles such as people, vehicles or other objects in its lane at an early stage, thus enabling safe driving operations with maximum personal protection," admits Neumaier's designer. The scanner's warning and protection field is controlled by the speed and adapts accordingly - the shuttle regulates its driving speeds continuously and, if necessary, until it comes to a standstill. In addition, other safety features and lighting systems such as direction indicators and BlueSpot were taken into account.

Smart and individual – the right thing for every customer process

Compact, manoeuvrable and customised - thanks to its standardised modular principle, the FS400 is versatile and can be adapted to any customer process and load carrier. In a wide range of payload versions, the FS400 series transports loads from 400 to 3,000 kg at speeds of up to 1.2 m/s - indoors and outdoors. The AGV offers everything that is necessary for modern and efficient factory automation and can thus be established as an integral part of daily operations.

"We have already designed everything in such a way that the whole concept can easily be transferred to other loads, sizes and load carriers," interjects Neumaier's designer. "The first AGVs are now transporting pallets and boxes from the automotive industry. These are special sizes and dimensions that we had to take into account directly in the design."

Neumaier Industry GmbH: the full programme

Every production environment and every application has special features - which is why Neumaier Industry GmbH sees itself as a true automation specialist. "We can manufacture all the components of an automated device ourselves, or rather have the years of experience and the corresponding know-how - from component from component manufacture to electronics, programming and mechatronics. The whole package fits with us," emphasises Managing Director Bernd Neumaier.

"There are now many AGV manufacturers, but most are standard. We offer the advantage of focusing specifically on customer requirements. Efficient and custom-fit solutions as a full-range supplier - everything from a single source: holistic consulting, custom-fit machines, fully comprehensive commissioning on site and training of the customer's personnel. We and our products always adapt to the customer and their requirements. The customer does not adapt to the product.

The Factory Shuttle FS400 from Neumaier Industry GmbH is convincing - automated, smart and self-organised, it improves not only the internal material flow, but also the entire value chain. Just-in-time provision of goods with short throughput times and optimal utilisation speak for themselves. "To achieve such a performance within a very short time is only possible because we have the experience in machine and vehicle construction as well as our own component production and mechatronics in-house," notes Neumaier's managing director Bernd Neumaier.

Watch the video on the application now!